MaXFlow in Material Science

Molecular Simulation and Artificial Intelligence Platform

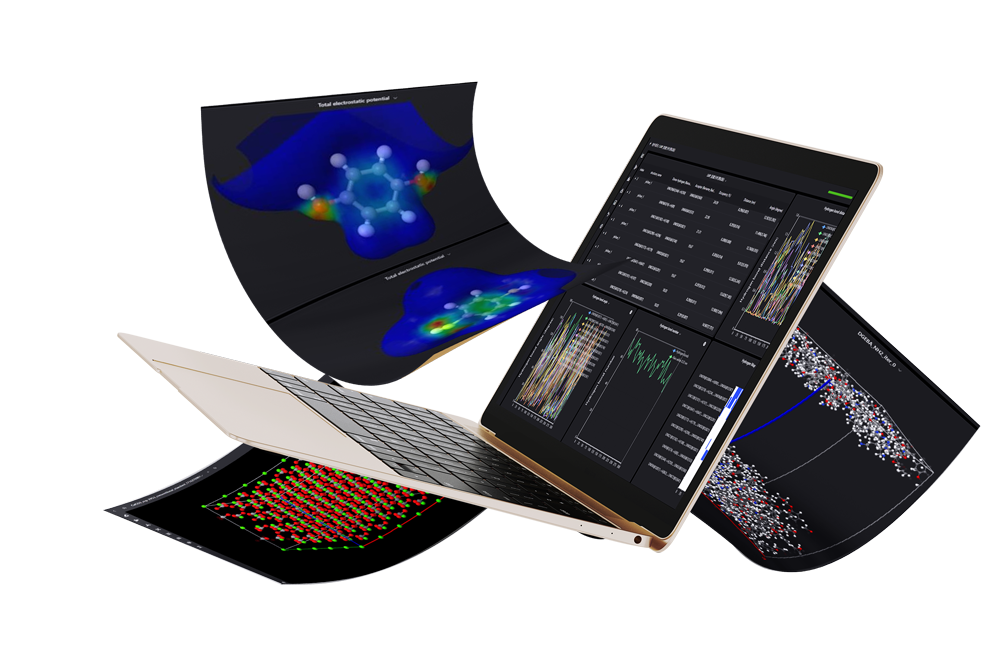

Powered by cloud computing and artificial intelligence, MaXFlow revolutionizes materials modeling and materials simulation, offering advanced tools for materials property prediction and AI design of experiments. This cutting-edge software enhances the design and performance prediction of new materials, empowering researchers to drive R&D efficiency and innovation in materials design.

Accelerate Material Design and Performance Prediction

MaXFlow’s molecular simulation capabilities are extensively used in materials physics and chemistry, supporting researchers in designing new materials and predicting their properties. The platform covers a wide range of materials, including thermoelectric, nano, energy, metals, semiconductors, superhard, superconducting, piezoelectric, nonlinear optics, catalysts, polymers, composites, and more, helping you push the boundaries of material science.

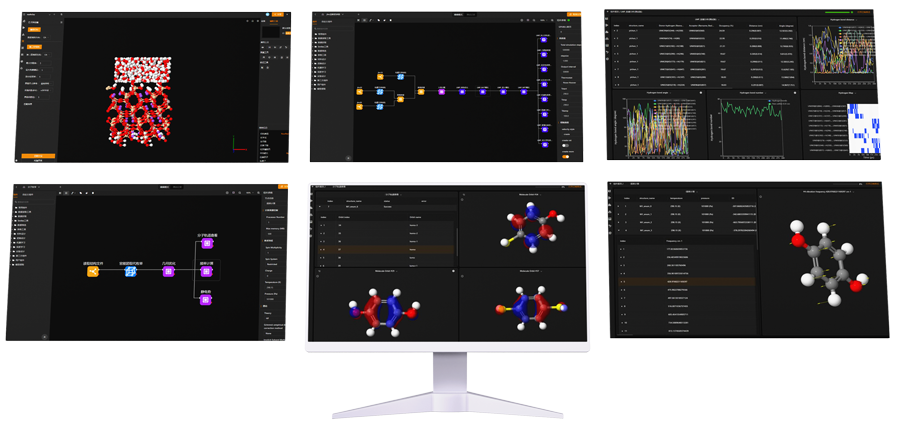

Key Features

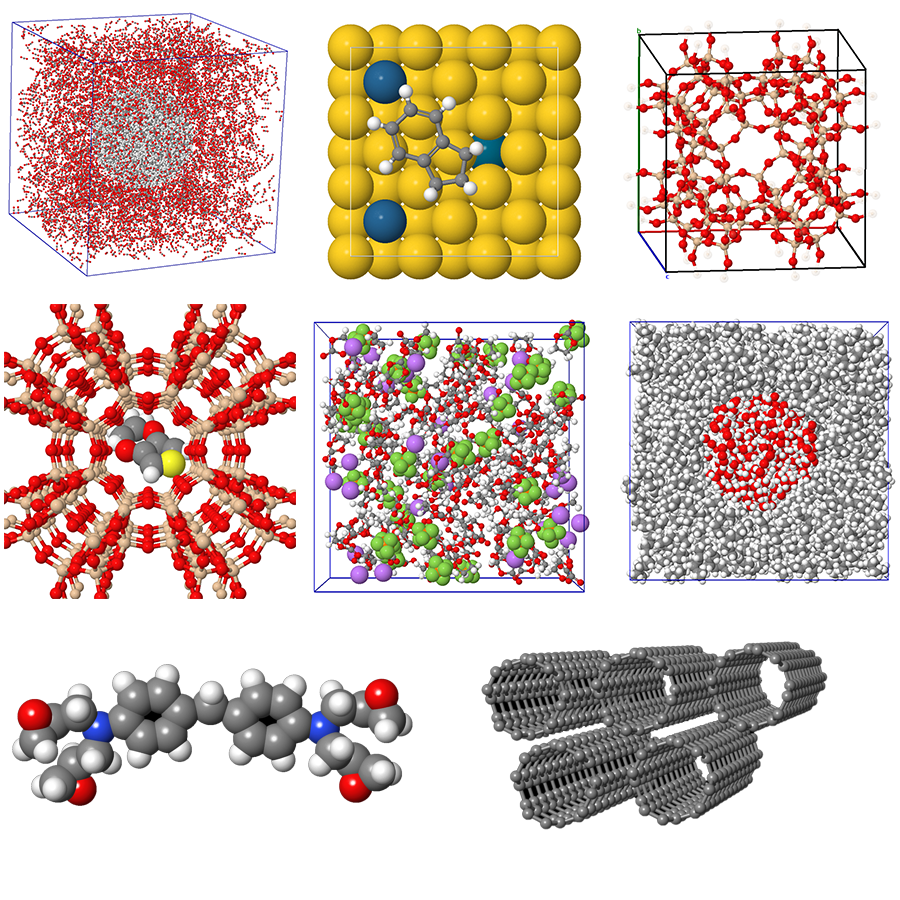

Innovative Microstructure Design

The “Crystal and Molecular” visualization interface allows users to construct and visually edit material microstructures online. This feature supports a variety of structures, including small molecules, polymers, crystals, surfaces, interfaces, amorphous structures, and nanotubes, enabling researchers to easily create models for diverse computational applications.

Advanced Complex Microstructure Modeling

- Cross-Linked Structures: MaXFlow provides a component to build cross-linked structures based on defined reaction mechanisms, allowing users to generate models with different degrees of cross-linking for advanced material studies.

- Molecular Compound Library: With functional group substitution enumeration tools, MaXFlow helps rapidly generate large compound libraries, facilitating high-throughput virtual screening and efficient exploration of material properties.

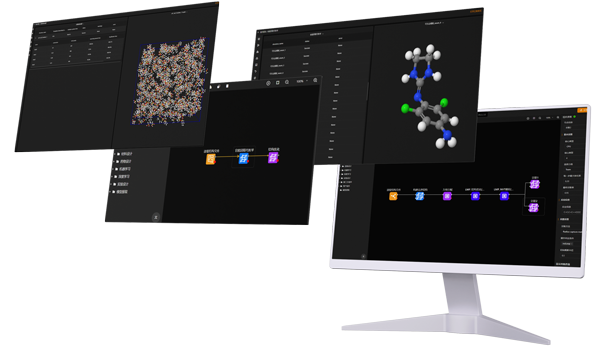

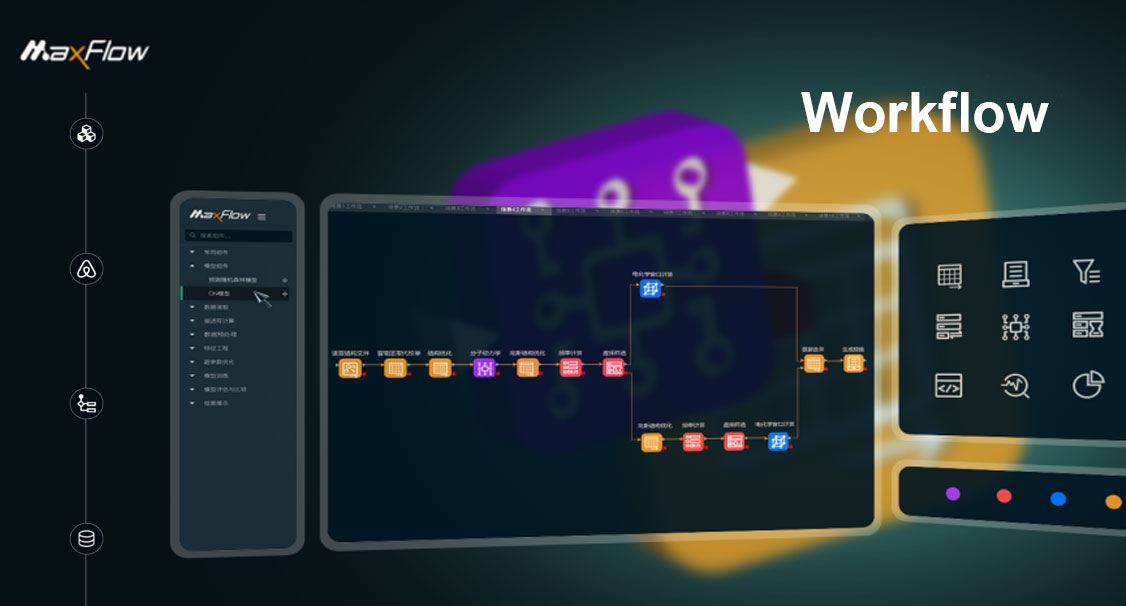

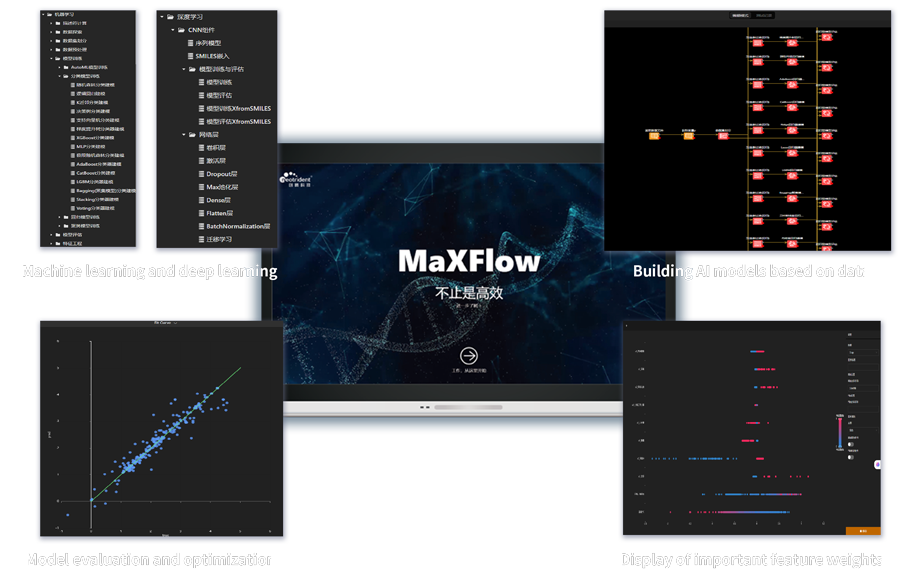

Simplified Workflows for Automated Calculations

Workflows are a core feature of the MaXFlow platform, automating complex, multi-step calculations into seamless processes. Users can easily build and customize workflows through a drag-and-drop interface, integrating pre-built and custom components to handle everything from basic simulations to advanced AI and experimental design. This flexible approach enhances efficiency, reduces manual effort, and accelerates research by enabling intelligent, automated computations tailored to specific research needs.

Flexible Computing Engines for Algorithm Freedom

MaXFlow supports a range of simulation engines, including QUANTUM ESPRESSO, PySCF, LAMMPS, RDKit, and RASPA, covering quantum mechanics, molecular mechanics, and dynamics. The platform’s graphical interface allows users to set parameters easily without needing to prepare input files manually, ensuring seamless integration between simulation, visualization, and result reporting, thus boosting research productivity.

Transform Complex Simulations into Easy-to-Use Apps

MaXFlow’s unique “APP release” feature converts complex modeling, simulation, and multi-algorithm workflows into simple, automated applications. This makes it easy for experimental scientists to design microstructures, build virtual libraries, and predict material properties, even without extensive computational expertise.

AI-Enhanced R&D Efficiency

In material science, AI aids in material design, optimization, data analysis, and formula development. By leveraging AI algorithms, MaXFlow accelerates the discovery and optimization of new materials, turning data into actionable insights and significantly enhancing R&D productivity.

Broad Applications Across Material Science

AI-driven models within MaXFlow have been applied to various materials, including new energy, perovskite, piezoelectric, catalysts, and semiconductors. AI models predict material performance and optimize formulas, processes, and costs, significantly shortening the development cycle of new materials.

Comprehensive AI Algorithm Support for Advanced Analysis

MaXFlow offers diverse data mining and machine learning algorithms, including classification, regression, clustering, CNNs, DNNs, and GNNs. These tools help manage, analyze, and extract valuable insights from large datasets, automating model creation, evaluation, and application to enhance data-driven decision-making in material research.

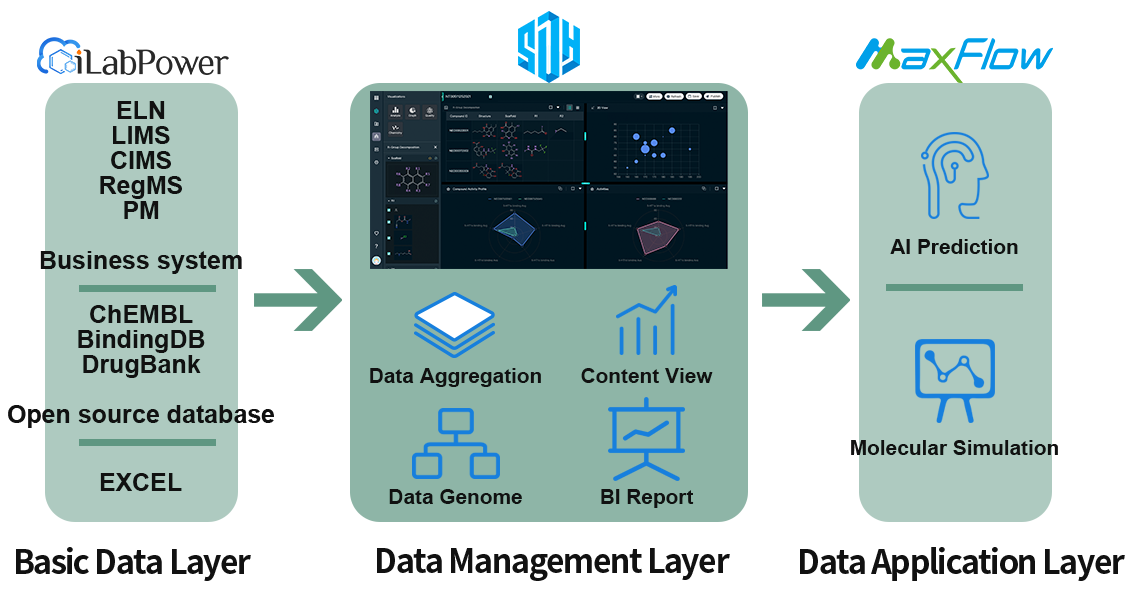

Seamless Data Integration with SDH

MaXFlow integrates with the SDH platform, breaking data silos and enabling seamless data flow between research functions. It connects with iLabPower for direct access to experimental data and provides public and private databases,such as Crystallography Open Database (COD), facilitating intelligent data analysis and support for AI-driven predictions.

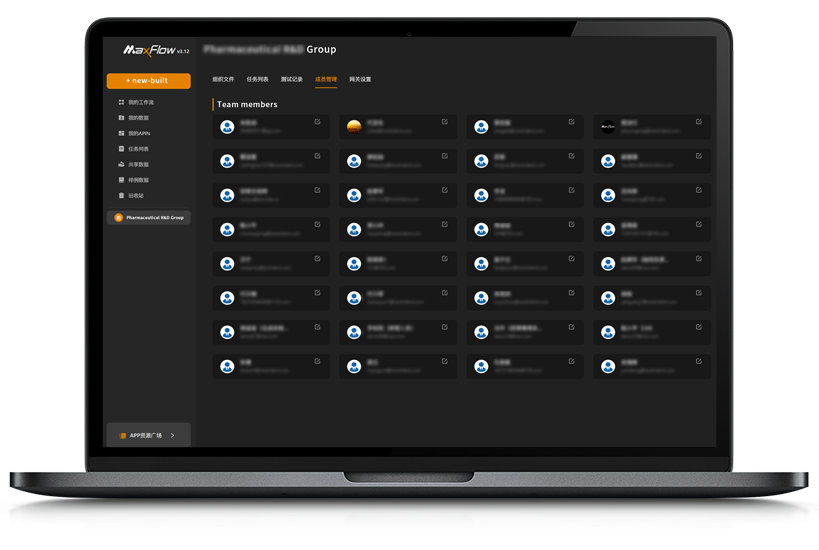

Platform-Level Advantages Over Traditional Desktop Simulation Software

Unlike traditional desktop simulation software, MaXFlow is a platform-level solution that offers comprehensive file management, user roles, and permissions management, ensuring data security and enhancing collaboration within teams. This platform approach supports the accumulation of data assets and facilitates internal knowledge transfer, protecting your company’s investment and building a sustainable foundation for long-term innovation.

Advanced AI Prediction Models

MaXFlow offers pre-trained AI prediction models to streamline your research and enhance material property prediction.

- Crystal Property Prediction Model (GNN-Based): Input a crystal structure file to accurately predict eight key properties, including formation energy (eV/atom), binding energy (eV/atom), band (eV), Fermi energy (eV), bulk modulus (GPa), shear modulus (GPa), and Poisson’s ratio, enabling precise evaluation of crystal materials.

- Polymer Property Prediction Model (GNN-Based): By entering the SMILES of a polymer monomer, predict critical electrical properties (e.g., atomization energy, bandgap, dielectric constant), optical properties (e.g., refractive index), and thermophysical properties (e.g., glass transition temperature), supporting rapid polymer analysis and design.

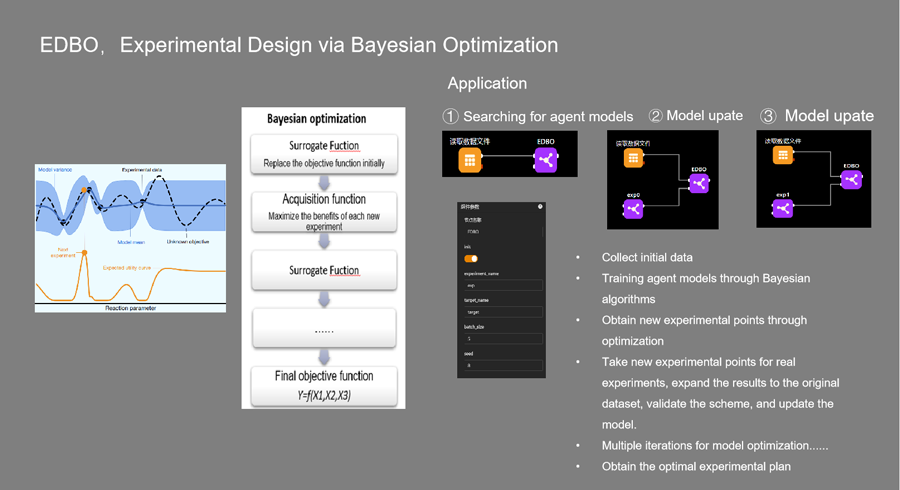

Intelligent Experimental Design with AI

MaXFlow integrates machine learning into traditional DOE methods, greatly enhancing optimization efficiency for formula design, synthesis, and process optimization, enabling smarter, faster decisions in experimental design.

Key Benefits for Your Organization

- Accelerate R&D Processes: Reduce time-to-market with automated workflows, high-throughput screening, and AI-driven insights that streamline material design and optimization.

- Enhance Data-Driven Decision Making: Access real-time data and powerful analytics to guide your R&D strategy, improving the accuracy of predictions and quality of outcomes.

- Reduce Costs and Improve Efficiency: Optimize experimental design and resource allocation, cutting down on costly trial-and-error and focusing efforts on the most promising material candidates.

- Increase Innovation Capacity: Leverage advanced simulations and AI models to explore new material possibilities, pushing the boundaries of what’s achievable in material science.

- Improve Product Quality: Predict and control material properties with precision, ensuring that new materials meet exact performance standards and customer expectations.

- Foster Collaboration and Knowledge Sharing: MaXFlow’s platform-level management of data, user roles, and permissions enhances team collaboration, supports the continuity of work, and protects the company’s data assets, ensuring that valuable research knowledge is retained and built upon.

Take the First Step Towards Intelligent

Innovation

- 1-626-8796699

- market@neotrident.com

- Unit C, 8/F Charmhill Center, 50 Hillwood Rd, Tsim Sha Tsui, Kowloon, Hong Kong

Company

- 1-626-8796699

- market@neotrident.com

- Unit C, 8/F Charmhill Center, 50 Hillwood Rd, Tsim Sha Tsui, Kowloon, Hong Kong